ES-100:

Steel bands - one per each end.

Adhesive strips on each side of overlap,

- To 18" diameter casing - One

- To 18" diameter casing - One

- 20" to 28" diameter casing - Two

- 20" to 28" diameter casing - Two

- Over 28" diameter casing - Three

- Over 28" diameter casing - Three

"Wrap-Around End Seals" are manufactured by:

Canus International Sales (2003) Inc, 20058 - 92A Avenue, Langley, BC, V1M 3A4, Tel: 604-882-1781

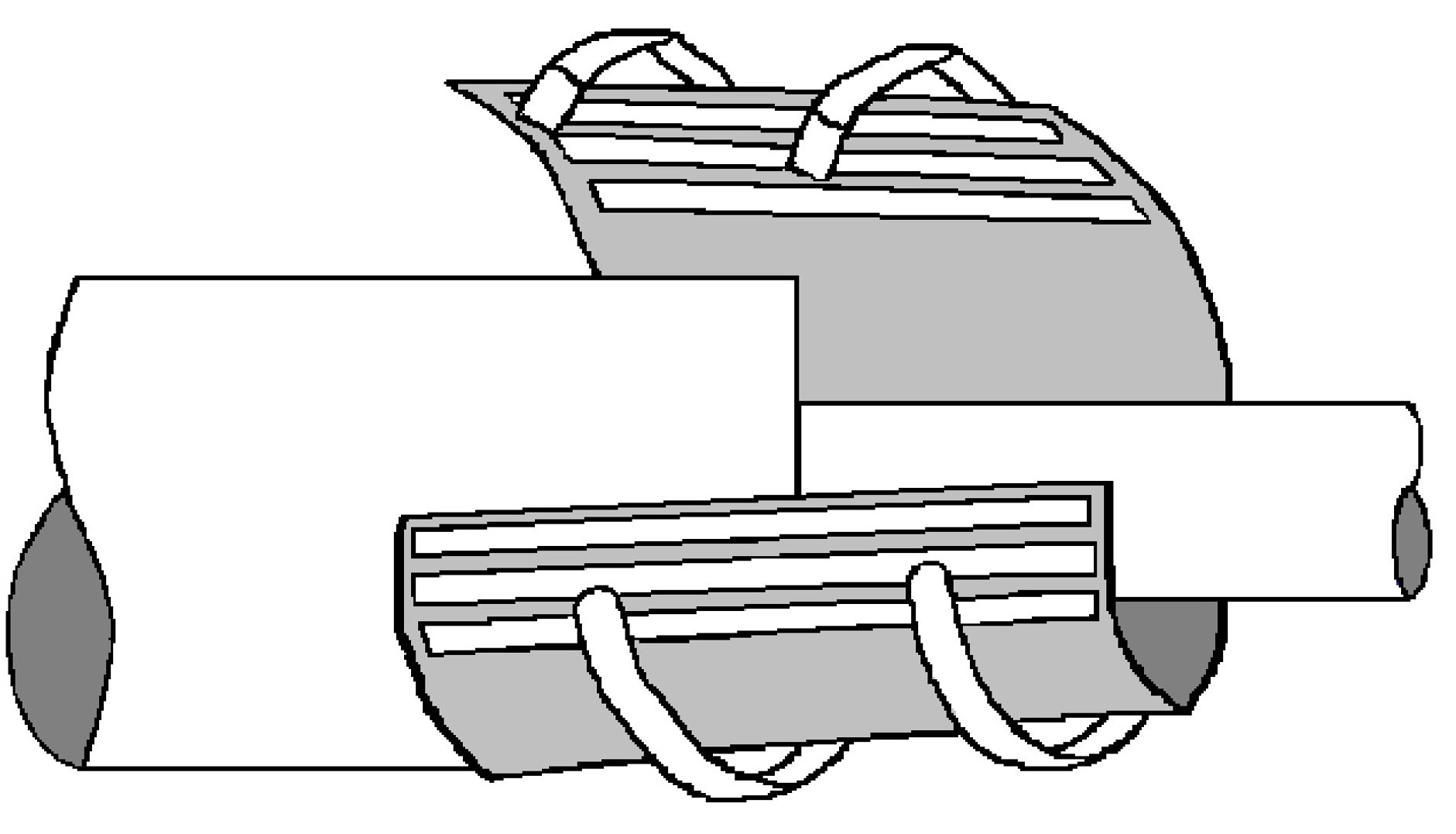

Canus "Wrap-Around End Seals" are used to seal the openings between casing/carrier pipe combinations. 4" Casing / 2" Carrier to 56" Casing / 48" Carrier.

ES-100 and ES-200 are fabricated, one piece, conical shaped seals that are produced to a wide range of casing/carrier sizes.

Seals are made from high quality EPDM rubber, 1/8" thickness, for superior oil, water and chemical resistance. Material provides strength and flexibility between casing and carrier pipe.

ES-100 and ES-200 are wrapped around once the carrier pipe is in position. The overlap is secured utilizing adhesive strips located on the inside longitudinal surfaces. The seal is scured to both the casing and carrier pipe using the 1/2" wide stainless steel bands with gear clamps.

A telescopic fold is usually made in the seal before banding to allow for casing/carrier movement.

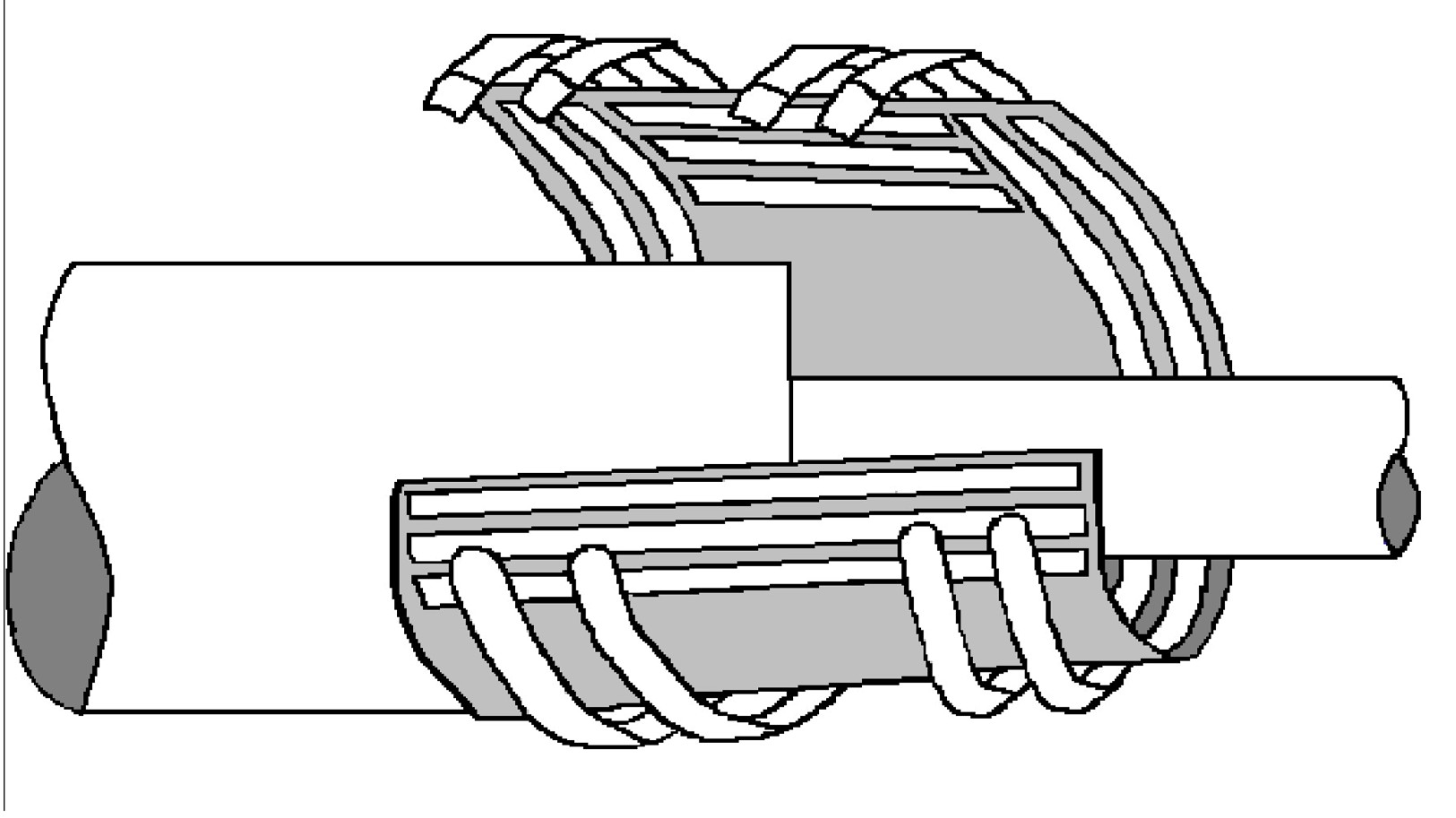

ES-200 seals have two 2" wide adhesive strips on the inside of both ends and two S.S. bands on each end. These are provided for conditions requiring a pressurized annulus between casing and carrier pipes.